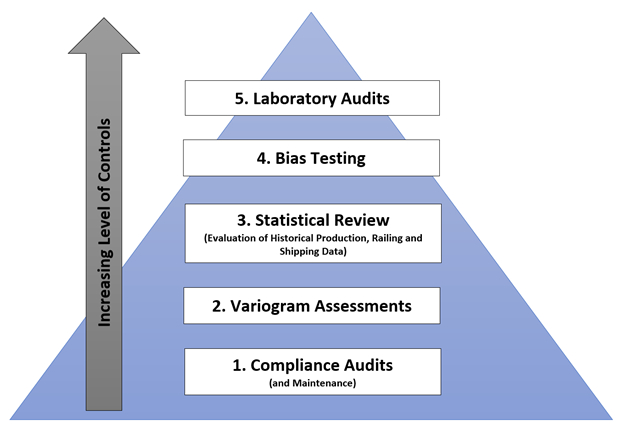

At A&B Mylec we have been completing Sample Plant Compliance Audits, which are NATA accredited, for over 15 years. We focus on a “Beyond Compliance” approach, meaning that ensuring your mechanical samplers are compliant to the standards is only a portion of what is necessary to achieve the best precision and accuracy in the production and operational analysis data that you generate. A combination of Compliance Auditing, Variogram Assessments, Bias Testing, Statistical Analysis (of production, rail and port data) and Laboratory Auditing is typically needed to obtain the best data to improve decision making.

The Sampling Systems Technology hub provides independently accredited expertise in all aspects of manual and automated sampling and metallurgical reconciliation across all aspects of the pit to customer chain. Sampling Systems Technology utilises its extensive knowledge of sampling practices and operational experience to develop sampling regimes that maximise quality control and reconciliation practices, while maximising safe sampling practices. Sampling Systems Technology is fully accredited for the inspection of mechanical sampling systems for both coal and other particulate materials including base and ferrous metals.

The Sampling Systems Technology hub is fully accredited with the NATA (National Association of Testing Authorities, Australia) as a Type A Inspection Body, and currently overseas dozens of mechanical sampling systems across Australia, Indonesia and Mozambique.

Sampling Systems Technology hub provides the following services amongst other.

- NATA Accredited Mechanical Sampling System Compliance Audits

- NATA Accredited Mechanical Sampling System Bias and Rolling Bias Testing

- NATA Accredited Mechanical Sampling System Precision Testing

- Conceptual Design and Redesign of Mechanical Sample Systems

- Design of a Variety of Sampling Tools to Achieve Relevant Australian and International Standards

- Design and Evaluation of Analytical Data From Sampling Programs

- Metallurgical Reconciliation Across All Aspects of Pit to Customer Bulk Material Chain

- Sample Preparation and Analysis Procedure Development and Review

Currently, several Australian and international ports as well a significant number of individual mine sites that utilise the expertise of the Sampling Systems Technology hub.

Accredited for compliance with ISO/IEC 17020.